Hastelloy C276 Mig Wire

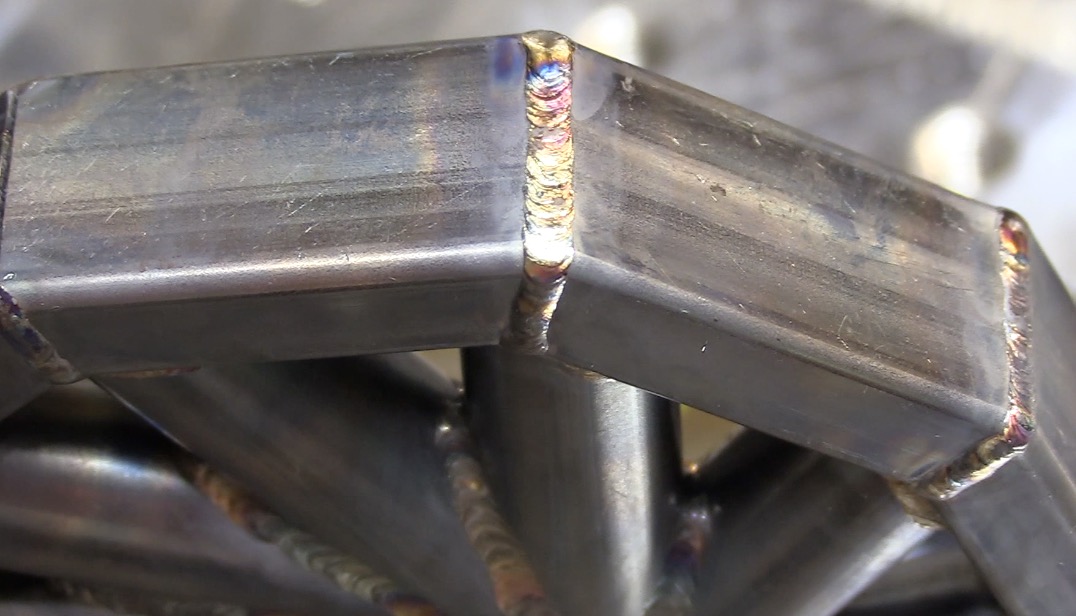

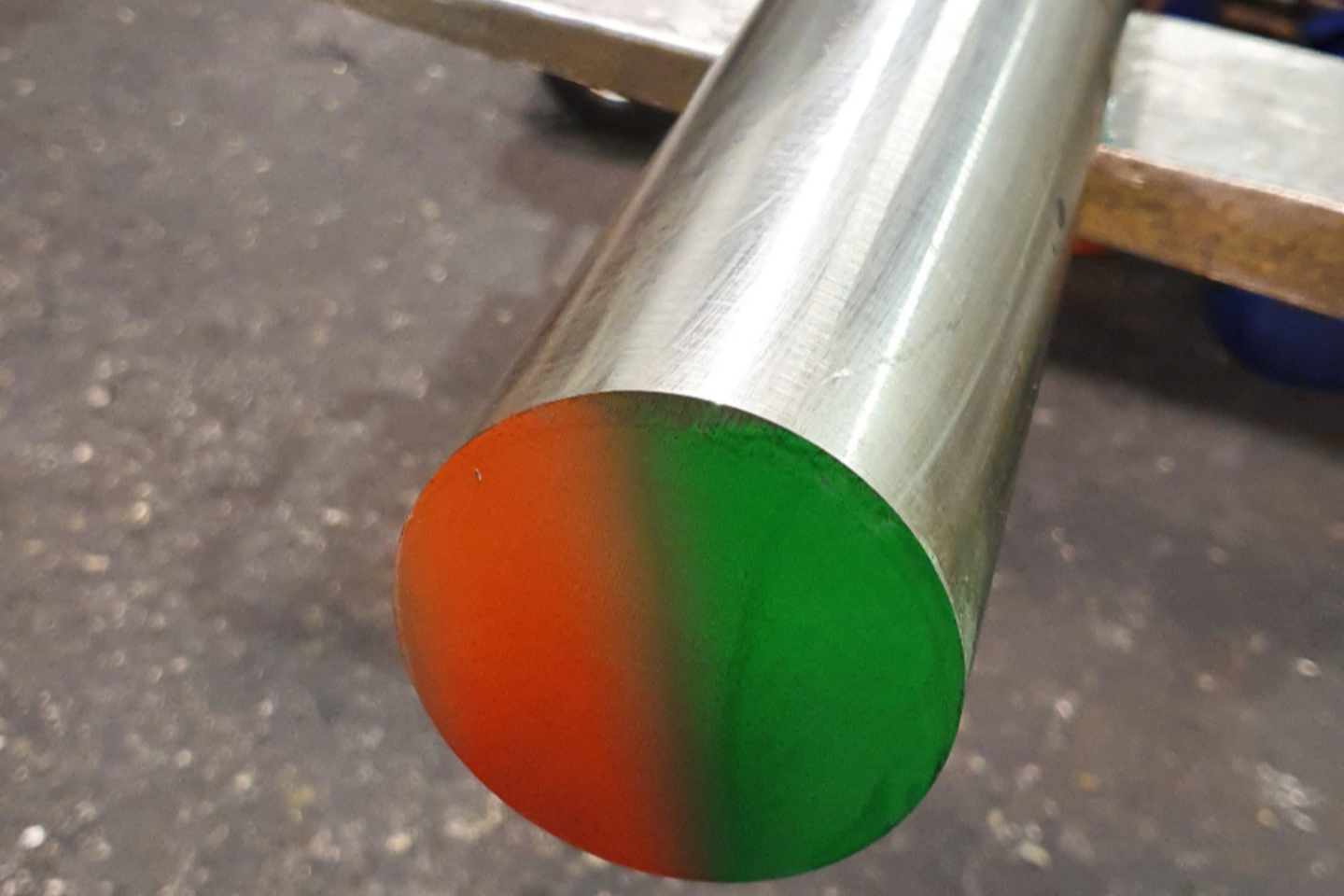

It is also used for surfacing of steel.

Hastelloy c276 mig wire. Hastelloy c276 wire can work in any corrosive conditions such as those found in waste management and pollution control. It is designed to match the composition and properties of alloy c276. Nickel c 276 is a nickel chromium molybdenum wire used for welding hastelloy c and hastelloy c 276 to themselves to stainless steels or to other nickel based alloys. The waste that is processed in these industries is often extremely toxic and needs an alloy that can withstand the toxicity.

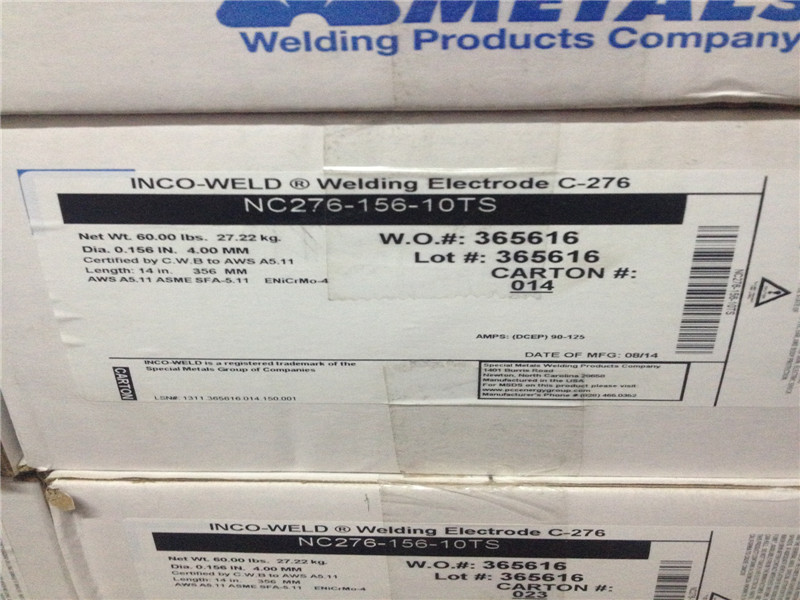

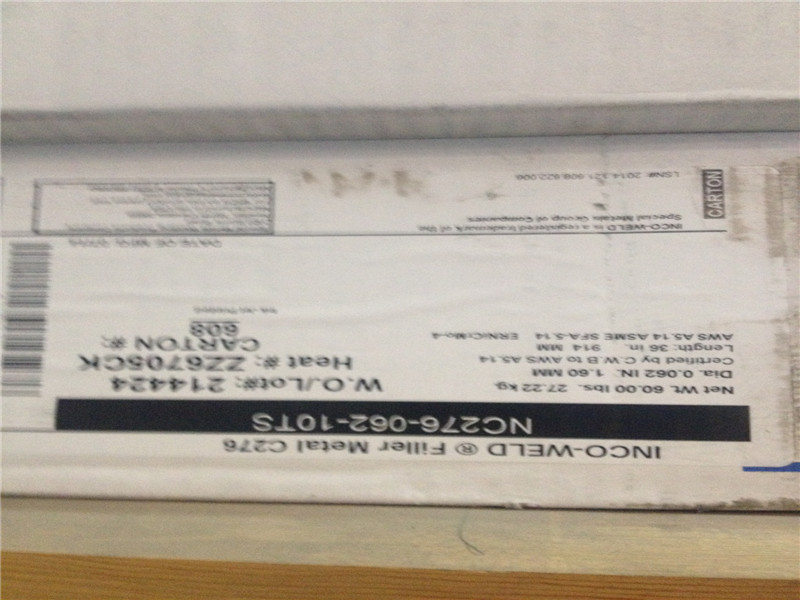

Dissimilar welding applications include other nickel chromium molybdenum alloys and stainless steels. Hastelloy c276 is a nickel chromium molybdenum filler metal developed for mig and tig welding of hastelloy c and hastelloy c 276 to themselves to stainless steel or to other nickel base alloys. The service performance of the welded component should be given the utmost importance when determining a suitable weld process or procedure. Solid mig wire for welding of alloy c276 applications.

Nickel c 276 offers excellent resistance to pitting stress corrosion cracking and oxidizing in atmospheres up to 1 900 f. Alloy c276 has high resistance to corrosion in a wide range of acids and salts. Techalloy 276 is a low carbon nickel chromium molybdenum filler metal that can be used for dissimilar welding between nickel base alloys and stainless steels as well as for surfacing and cladding. Aws a5 14 en iso 18274 ernicrmo 4 sni6276 applications.

This is similarly true for the paper producing industry that uses chemicals to treat their products. The hastelloy and haynes alloys are known for their good weldability which is defined as the ability of a material to be welded and to perform satisfactorily in the imposed service environment. Hastelloy c 276 rtw filler metal is used for the gas metal gas tungsten arc and submerged welding of c 276 alloy. Hastelloy c 276 is also a good candidate for overlay and cladding of steels when enhanced corrosion resistance is required.

A 4 54kg packet of 2 4mm ernicromo 4 c276 filler metal used in the welding of c 276 and other nickel chromium molybdenum alloys from special metals. Washington alloy c276 offers excellent resistance to pitting stress corrosion cracking and oxidizing atmospheres up to 1900of. Solid wire for nickel base alloy c276 specifications. Cast versions of the alloy typically have higher carbon and silicon like the original wrought hastelloy alloy c now obsolete but repair welds are usually solution treated for optimum corrosion resistance.