Hazardous Area Lighting Regulations

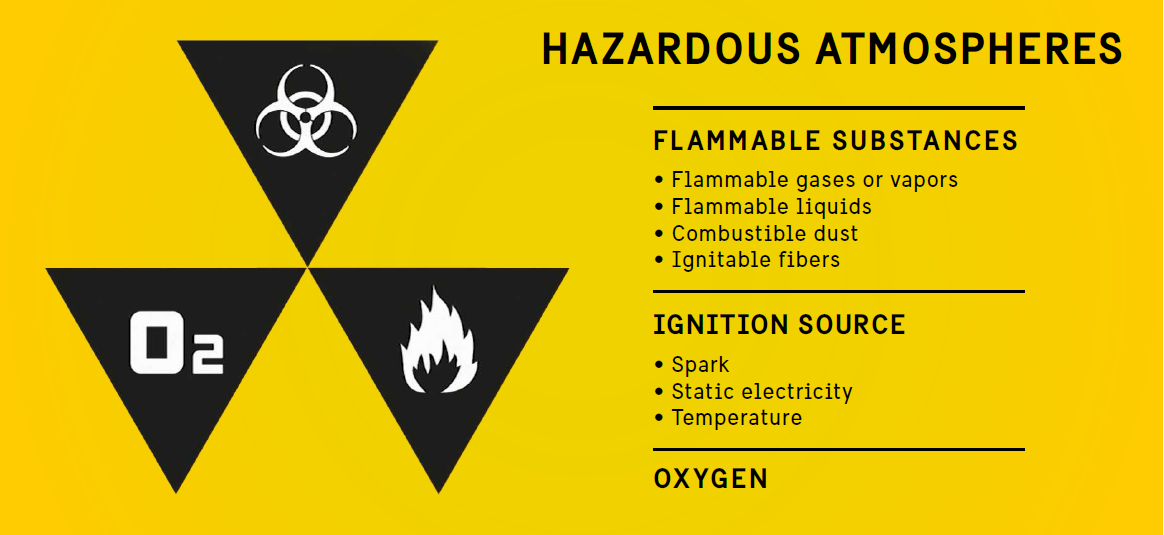

1910 307 a scope 1910 307 a 1 applicability this section covers the requirements for electric equipment and wiring in locations that are classified depending on the properties of the flammable vapors liquids or gases or combustible dusts or fibers that may be present therein and the likelihood that a flammable or combustible concentration or quantity is present.

Hazardous area lighting regulations. Various mounting options and multiple optical beam angles to meet any project requirements. Explosion proof self contained lights the employer shall provide and ensure that each employee uses only explosion proof self contained temporary and portable lights approved for hazardous conditions by a nationally recognized testing laboratory nrtl in any area that the atmosphere is determined to contain a concentration of flammable vapors that are at or above 10 percent of the lower. The all aluminum housing and isolated driver housing provides for extremely efficient heat management to ensure that the fixture maintains its performance for years to come. Title 29 of the code of federal regulations section 1926 56 sets out the candle feet of light required for various types of work.

For some areas such as flammable hazardous locations explosion proof led lighting is a must. A foot candle is the most common unit of measurement used by lighting professionals. Thorne derrick international based in the uk are the leading supplier of atex lighting for safe and reliable lighting of hazardous areas and locations this includes lighting for hazardous areas certified by the atex directive for use in zone 1 and zone 2 gas potentially explosive atmospheres in both onshore and offshore locations. The nfpa establishes area classifications based on classes divisions and zones that when combined delineate the hazardous conditions of a specific area.

Lighting these type of businesses is a tough challenge but can be achieved by installing atex certified hazardous area lighting products. Hazardous location area lighting cob ex. Explosion proof led lighting is also utilised in spray and paint booths. The relevant level 2 criteria are 5 2 1 3 29 c 5 2 1 11 63 f 5 2 1 13 and 5 2 4 2 93 a.

Hazardous area classification and control of ignition sources. This technical measures document refers to the classification of plant into hazardous areas and the systematic identification and control of ignition sources. A range of iecex certified lighting products for hazardous area locations including fluorescents well glass lights floodlights and led lights. It refers to the illuminance of one square foot surface from a uniform source of light.

An led linear light fitting suitable for use in zones 1 2 21 22 applications. This classification method provides a description of the hazardous material that may be present and the probability that it is present so that the appropriate equipment may be selected and. Hazardous area lighting.