High Bay Racking Inspection

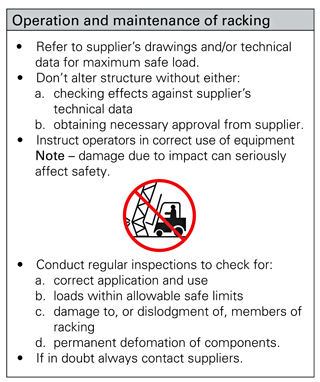

All of the above issues can be prevented by implementing an inspection and maintenance cycle for your warehouse racking.

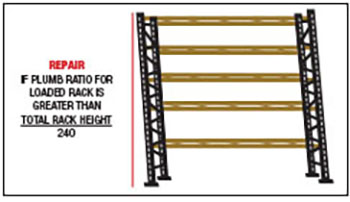

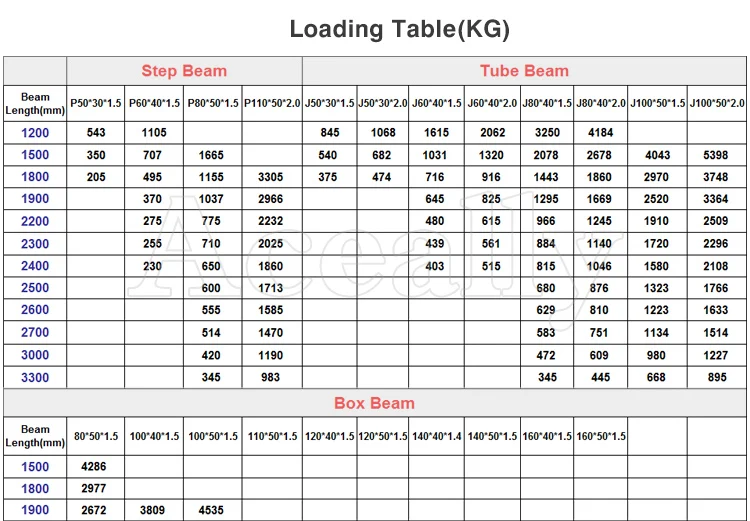

High bay racking inspection. In order to maintain safety a pallet rack s maximum load should be clearly posted to avoid overloading and prevent damage to the racks. Rather it s a general stacking requirement to keep materials from falling over or collapsing. 1910 176 b states that stored items must be secured. Pallet racks should be inspected upon installation and periodically checked for damage.

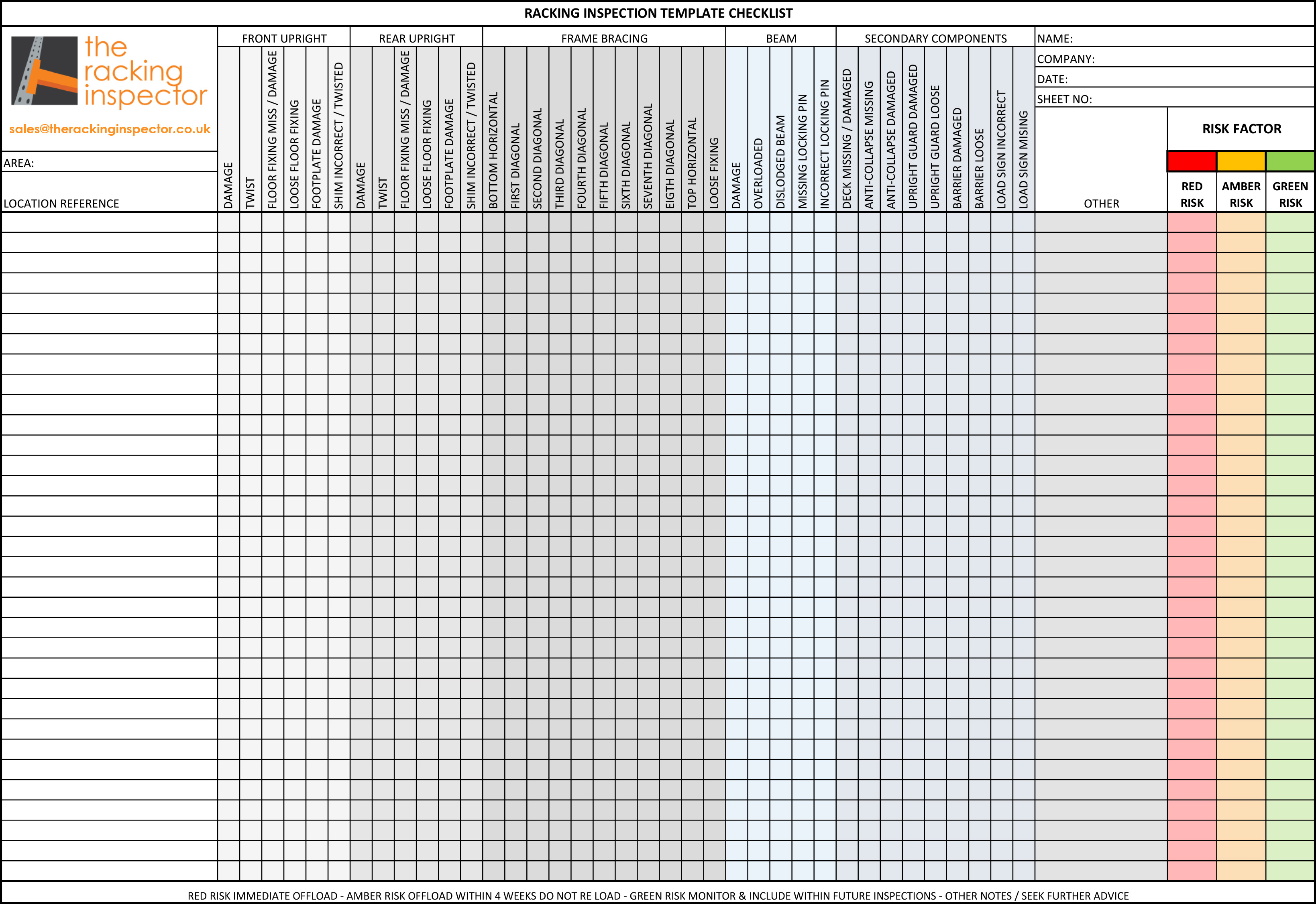

A racking inspection checklist details exactly which components of the racking system an inspector should be looking at frames beams and braces. The traffic light system is used to measure the damage severity and indicate the risk level. Some of the racking systems available through asp allow vehicles to be moved between aisles to reduce initial capital costs. Regular inspection of racking should be conducted both in house and independent to check its integrity identify maintenance requirements and to ensure racking is not overloaded.

Our pallet rack inspection services are non disruptive to your daily operations. Rack inspection certification service. Our engineers walk your facility and thoroughly inspect your racking systems for conformity by collecting on site information taking pictures and recording any deficiencies damages or missing components. Do not exceed the safe working limit swl for the unit load or the safe working total load per bay for the racking.

Each color corresponds to a required action for record keeping and monitoring.