High Bay Racking Safety

As the truck enters the racking special precautions apply to ensure the compatibility of design between the truck pallet and load and the racking.

High bay racking safety. Where do i find the requirement to anchor pallet racking. High bay industrial storage systems can exceed 60 in height nearly doubling the storage capacity of conventional systems fully automated and man up vehicles available. There are only two applicable rules. Some of the racking systems available through asp allow vehicles to be moved between aisles to reduce initial capital costs.

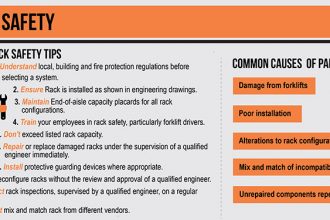

The truth is when it comes to warehouse racking safety guidelines osha doesn t offer much guidance. Lazy assumptions are enemies of safety and hse knows that this is definitely the case when it comes to racking safety. Load ratings not present on racking osha recommends that load ratings be present which provide the maximum permissible unit load and or maximum uniformly distributed load per level the average unit load and maximum total load per bay. Meters high and 4 to 5 but occasionally even 10 deep.

See ansi rmi mh16 1 for additional information. Flat floor is advantageous. In situations where pedestrians can access the back of the racking and single rows have been installed rear protection should be fitted to prevent loads falling out of the back of the racking. And i was very pleased with the response.

This system can provide very dense storage capacity often low n access and rotation of products. 1910 176 b which effectively states that material stored in tiers must be made safe and 1910 159 which covers fire sprinklers and essentially requires 18 inches of clearance between the rack and the. January 1 2016 last month i asked readers for ideas we could discuss on the blog. One follower submitted this commonly asked question to be discussed.