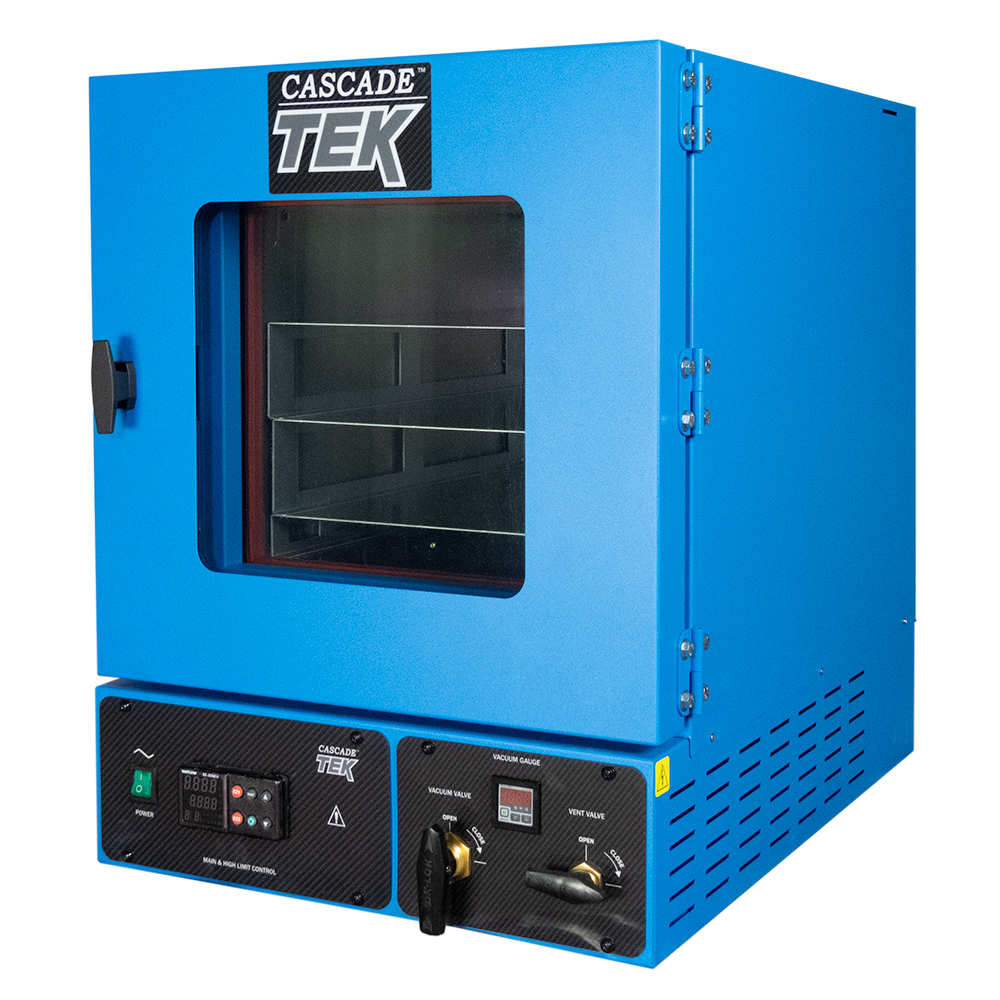

High Vacuum Bake Out Oven

Vacuum components can be bake out to achieve a further reduction of the outgassing rate.

High vacuum bake out oven. Therefore the material surfaces are released from adsorbed particles at high temperatures e. 300 c while the diffusion of molecules in. Vacuum ovens provide the ultimate in product drying outgassing bake out and moisture removal. Vacuum bake out of parts application note 05 07.

A vacuum bake out is a process used to remove such contaminants. This system provides excellent film performance much higher throughput and lower coo than atmospheric curing and delivers superior mechanical thermal and electrical properties for a large variety of polymers for wafer level packaging wlp applications. Many high and ultra high vacuum applications as well as high purity applications require parts that are free from absorbed volatile materials that may contaminate the system. Heavy walled all stainless steel chamber to eliminate flex stress.

To achieve pressures in the ultra high vacuum range 10 8 hpa the following conditions must be met. Ideal for space flight hardware connectors cubesats or any vacuum process requiring vacuum in the high vacuum range up to 1 0 x 10 6 torr. Yes vertacure is a production proven automated vacuum cure system equipped with 5 zone uniform temperature control and laminar gas flow. This allows the customer to pipe argon helium and nitrogen to the oven and use the same purge gas that the cylinder will be put into service.

Different pumping systems available for ultra clean ultra high vacuum processing as required. The svo 10t turbo is a fully automated high vacuum drying oven built to execute your unique bake out or drying process. Vacuum bake out ovens with temperatures up to 350c. Bakeout in the vacuum oven.

Vacuum drying product brochures standard tvac test systems overview lvo series vacuum oven 18 x 24 cylindrical lvo series vacuum oven 20 cube hvc 2500 heat vacuum controller hvc 3500 thermal vacuum controller standard tvac bake out systems standard tvac thermal cycling systems. Heated and water cooled shelving available for the precise temperature uniformity. The removal of impurities allows vacuum baked components to be used in ultra high vacuum or ultra high purity systems without fear of contamination. The base pressure of the vacuum pump should be a factor of 10 lower than the required ultimate pressure.

Cascade tek is happy to offer everything you need for a complete vacuum drying system including dry or wet vacuum pumps connection kits and a variety of replacement door gaskets suitable to your application. A vacuum bake out is a process used to remove such contaminants from products. The desorption and diffusion rates of all materials are highly temperature dependent. Applying surface heat normally up to 392 f 200 c is required to successfully complete a vacuum bake out process.

Absorbed water vapor is the most common contaminant.