Homemade Composite Curing Oven

The only down side is that some of the used ovens you ll find are super dirty.

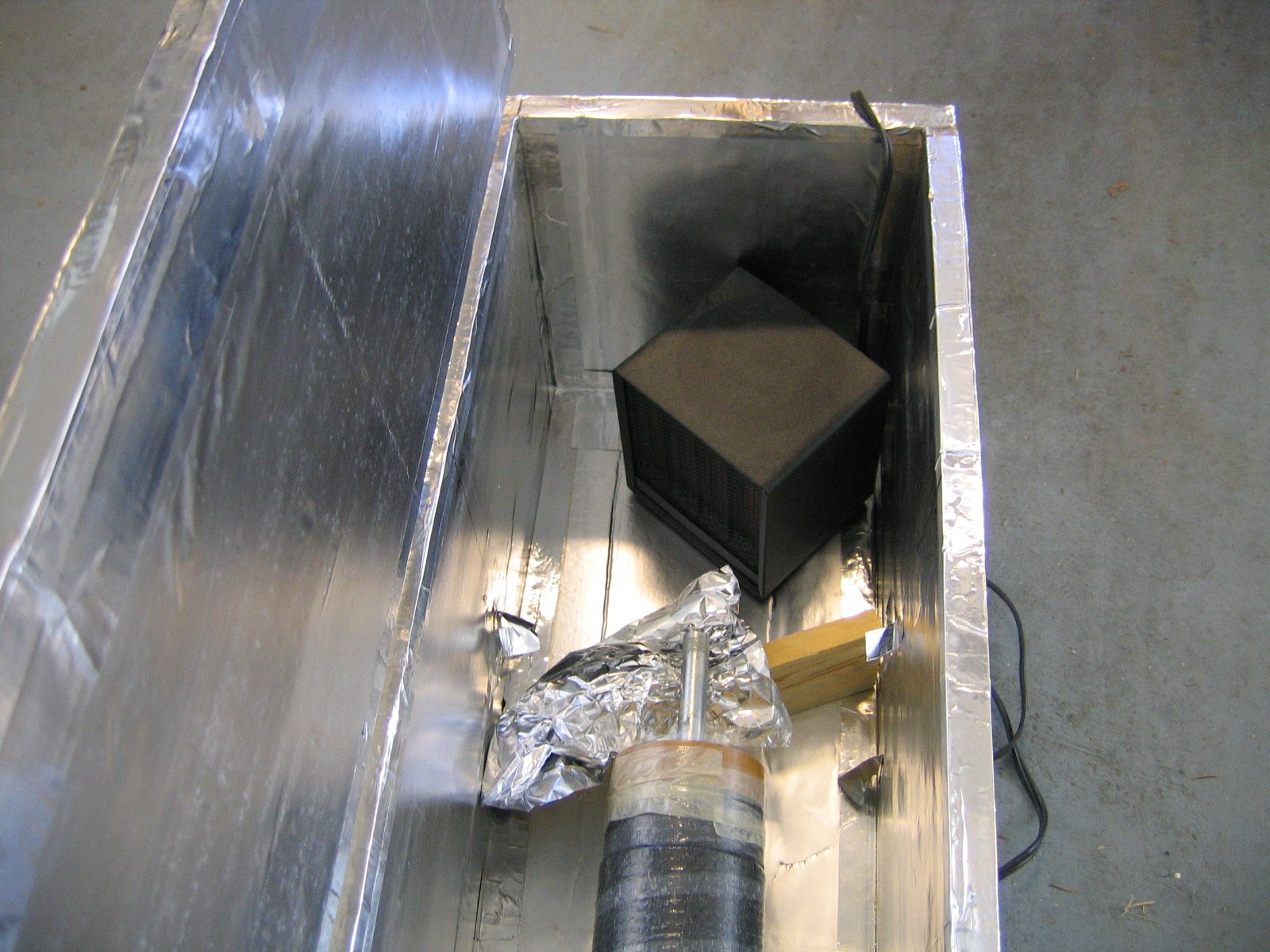

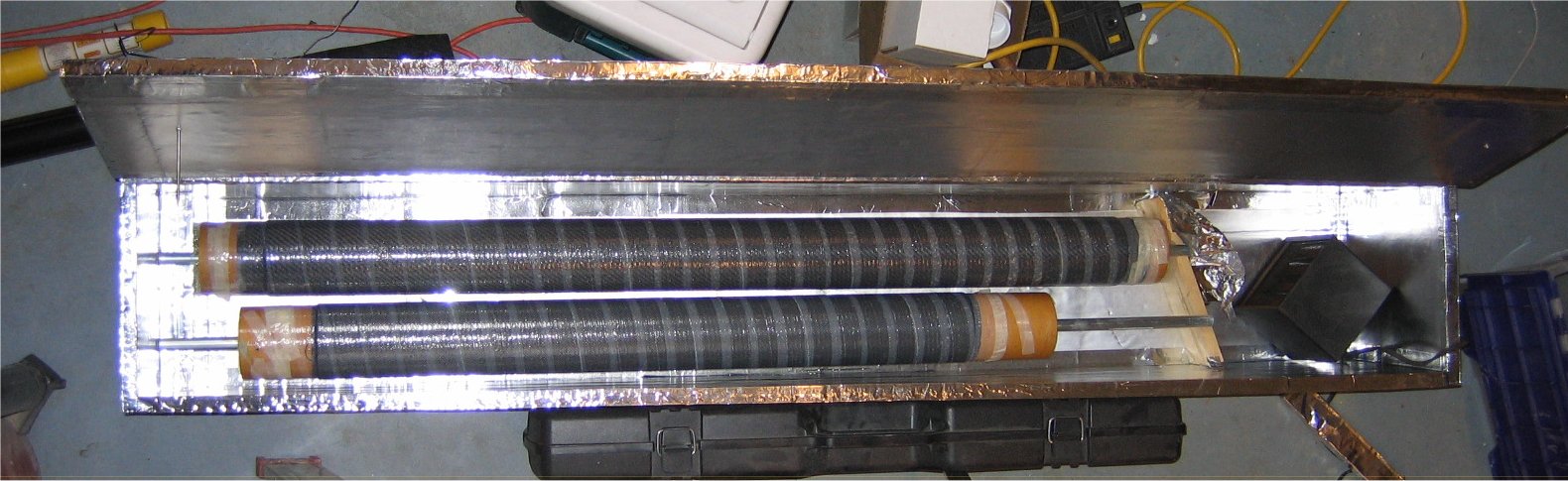

Homemade composite curing oven. This large hot box is controlled via a digital thermostat. Our duct design provides a side and up airflow design. Traditionally most composite parts required autoclaves for proper curing. Companies in industrial industries including aerospace automotive and sporting goods among others depend on its composite curing ovens to cure high strength low weight carbon composite materials.

Recent developments were reviewed in the sampe tech 2013 oct 21 24 wichita kan usa paper no oven no autoclave processing for nasa composite structures including construction of a 127cm by 66cm 50 inch by 26 inch carbon fiber skin aluminum honeycomb sandwich part and a 117cm by 107cm 46 inch by 42 inch curved carbon tool as preparation for building a 1 10 scale payload. Despatch composite curing ovens and composite curing walk in ovens deliver exceptional thermal curing technology performance for aerospace grade composite parts integrated multi port vacuum system and jack panels to connect as many thermocouples as needed for monitoring the curing process. But my curing oven is made from 100mm foil backed insulation board. Thermal curing is a critical step in manufacturing quality composite materials.

Mar 13 2013 1 in the process now of building a curing oven for cerakote. You could also use a pwm controller to regulate power. Here are some key features of our composite curing ovens that will keep you 100 satisfied for the long duration of your operation. Out of autoclave composite curing oven for advanced composites.

Many industries use ovens for drying curing and heat treating and the demands of composite processing are pretty tame by comparison. The efficiency of our burner gas train components flame safety and airflow design will ensure operating cost savings and the best possible heat processing accuracy available in the world. Sep 19 2012 674 25 34 42 chugiak alaska. In this example a custom built oven is lowered over a large mold max silicone mold.

This vertical hot box is large enough to accommodate very tall molds for crystal clear castings. A professional industrial oven would probably be looking at 20 of the overall time with the heating element powered on. Sniper s hide forward operating base. Start date mar 13 2013.

A good efficient oven is one that can insulate the heat so that the heating element only needs to be on for a minority of the curing time. Today low cost out of autoclave curing of aerospace grade composite parts is possible using a vacuum bagging system with a walk in batch oven. Our thermal airflow design experts design build and install ovens renown for their temperature uniformity and state of the art.