Honeywell Refrigerant Detection System

Easily configured to meet ashrae 15 b 52 and international mechanical code requirements the 301em is commonly used to optimise gas detection in mechanical and chiller rooms.

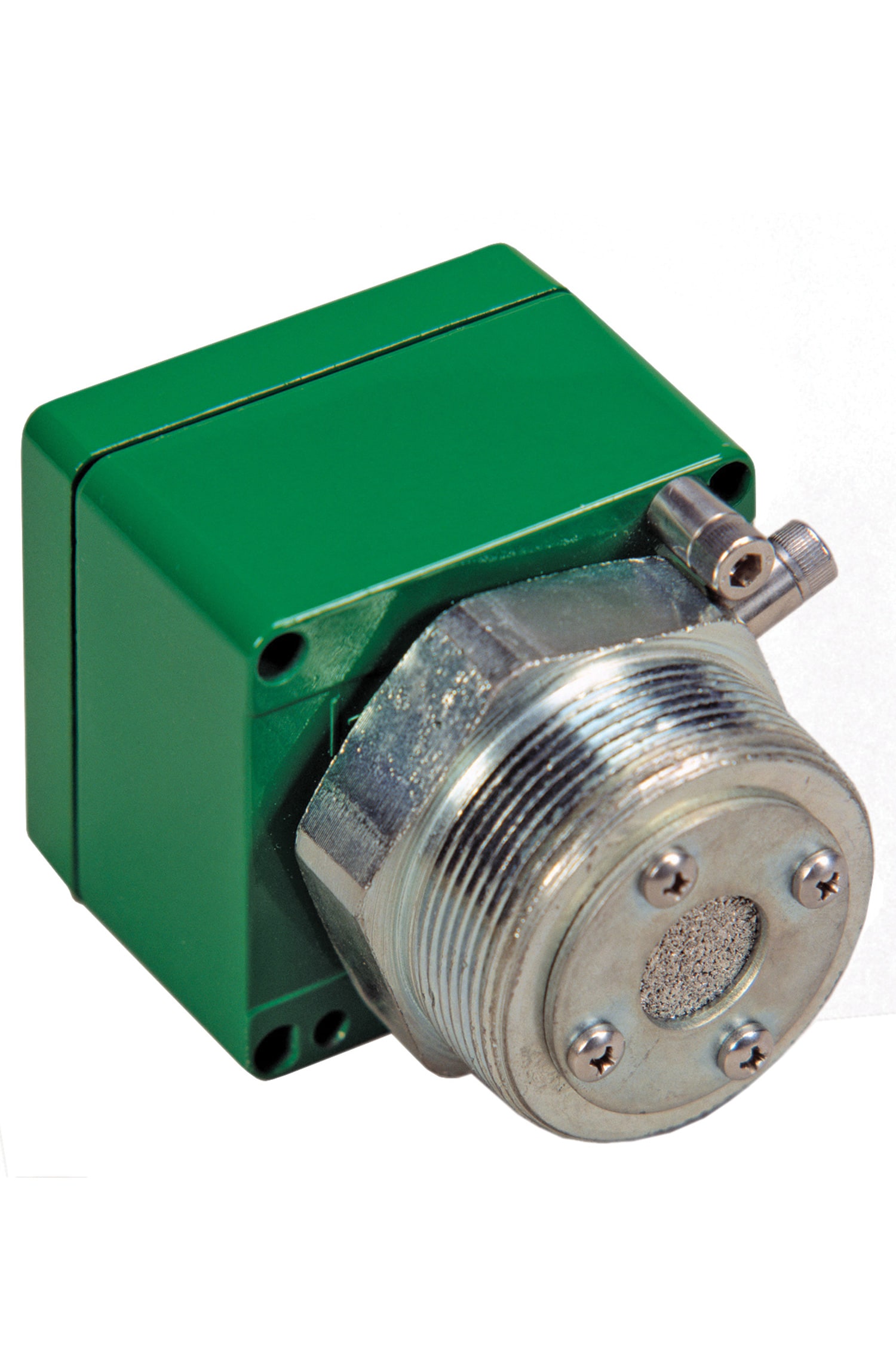

Honeywell refrigerant detection system. Whether there s a need to monitor carbon monoxide from vehicular exhaust in parking structures carbon dioxide levels in auditoriums or conference rooms ozone depleting refrigerant gas leaks in mechanical rooms toxic off gassing from equipment or flammable gas leaks in pipes and equipment honeywell offers a total gas monitoring solution for you. The manning vent line leak detector is designed to be electrically connected to and monitored by all honeywell analytics readouts or can send a signal directly to a plc. Today honeywell s gas leak detectors have evolved to meet the requirements of diverse industries and applications delivering comprehensive solutions designed to drive down the cost of gas detection while providing. The 301em can be configured to offer automatic fan horn and strobe activation in addition to manual fan activation when the 301irf detects a refrigerant.

A full complement of sensors including toxic oxygen combustible gases and a full line of refrigerant sensors horns strobes and remote panels provide added. This includes but is not limited to central utility plants boiler and chiller rooms mechanical and electrical rooms fuel rooms as well as metering and communications closets. Honeywell s historic products set new benchmarks for gas detection in terms of performance ease of use and innovation. Honeywell s 301irf together with the 301em mechanical room controller provides a complete solution that meets and even exceeds these rigorous standards.