Hook Load Sensor Deadline

Hook load and vernier dampers are designed to dampen excessive pointer movement and extreme shock during tough drilling situations.

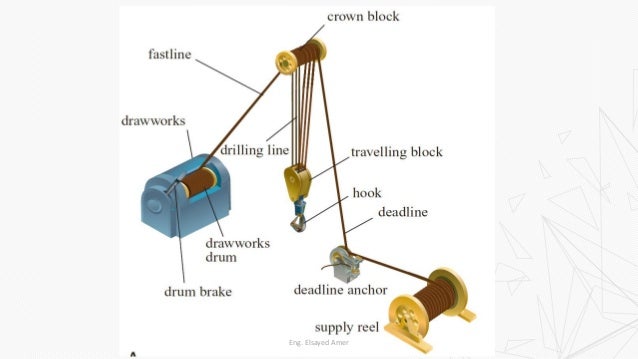

Hook load sensor deadline. Anchor type indicators use tension load cells or compression cells to accurately read the hook load and provide the drill with weight on bit. The standard configuration uses a rosemount e 1144 go 600 psi pressure transducer. This total force includes the weight of the drillstring in air the drill collars and any ancillary equipment reduced by any force that tends to reduce that weight. Some forces that might reduce the weight include friction along the wellbore wall.

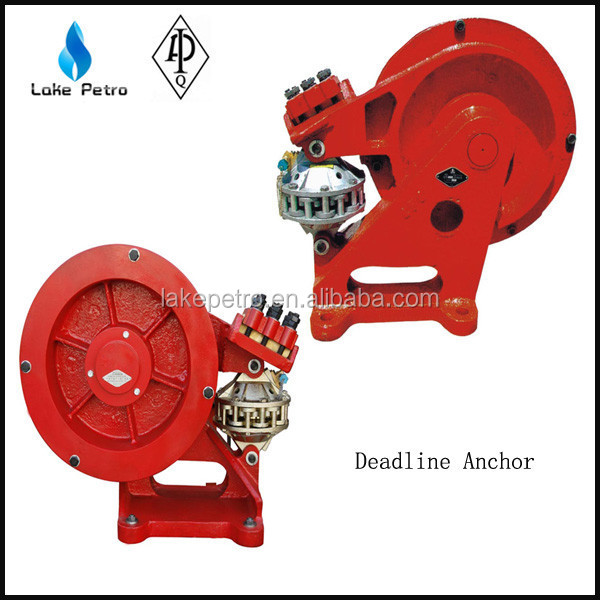

The sentec range of precision proximity sensors were our first products and helped our clients in the semiconductor equipment. The hookload sensor normally used is a pressure transducer which ties into the rig s deadline anchor system. Units 14 16 whitegate industrial estate. Type 200 awe series for deadline loads to 200 000 lbs.

Hook load english español. 44 0 1978 364 586. Many models have separate pointers for both hook load and weight on bit. Includes a high pressure hose and disconnect fittings.

The initial range of products came from our partner in japan shanoc. In addition integral circular hydraulic recorders are also offered on several models. Models available for deadline loads of 30 000 to 200 000 pounds. 44 0 1978 363 888 and 0 845 658 2020.

The following instructions apply to the electrical aspects of the hook load sensor covered by the following certificate numbers. Models available for deadline loads from 30 000 pounds to 200 000 pounds indicator includes outer dial vernier for direct weight on bit reading and inner dial for total hook load. The span of the sensor can be varied from 0 150 psi to 0 600 psi to match the rig system and provide the optimum signal range. Once the pressure reaches the indicator the outer dial measures weight on bit and the inner dial measures total hook load.

Each system accurately senses tension in the deadline and uses this to indicate hook load and weight on bit. Includes vernier bit weight indicator with 4 1 sensitivity for highest possible accuracy. Our weight indicator systems use load cells sensors or chart recorders to accurately define tension weight or compression. When the load cell is compressed hydraulic fluid is forced through the load cell to the weight indicator by way of a high pressure hydraulic hose.

Gauge includes outer dial for direct weight on bit reading and inner dial for total hook load.